Muller Martini EMP 513 Casing-in Machine with building-in Machine

For casing-in of flat spine book blocks into hard covers, as well as subsequent pressing and joint-forming of books.

To be used as an individual machine.

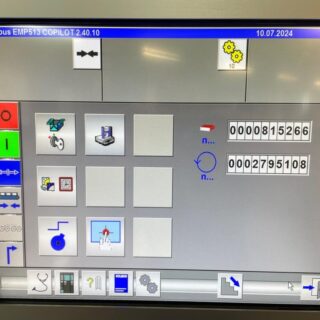

– copilot system with 2 touch screens

– block supply via feeding conveyor and star feeder

– case pre-stacking conveyor

– case magazine

– case bending machine

– case forming station

– casing-in gluing station with profile rollers and adjustable double glue application for the book joint area

– rubbing down unit and thin block device

– glue circulation system with pump

– EMP glue pump monitoring unit

– Rubbing down unit and thin book device

– Electronically heated 15° joint forming rails, controlled in pairs via regulator

– quick-change system for joint forming rails

– 2 pressing stations

– heater monitoring unit

– servo-controlled drive technology based on Siemens SIMOTION D

– delivery to the left, transport of books lying flat

additional equipment:

– photo book block splitter

– Hotmelt nozzle gluing unit for joint gluing

– Nordson premelter

– Code-Matching (comparison) between book block and case via data matrix code Barcode sensor: Cognex camera

– double case control

– special equipment for the processing of flexible cases

Transport conveyor system