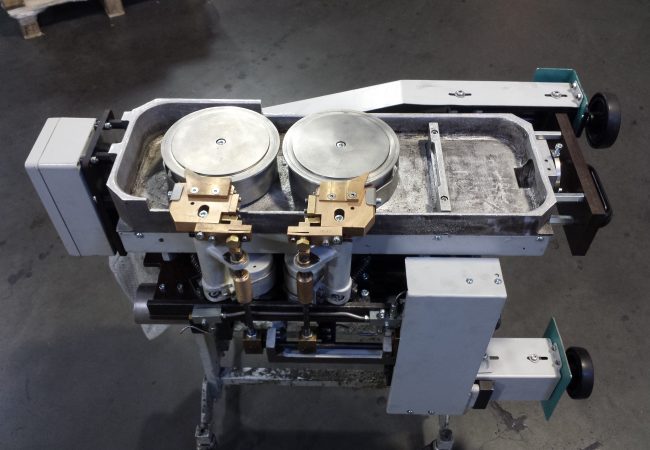

PUR coating service and glue pot rebuilds

Why coating?

Even the best coating will eventually wear down and cleaning the pot is going to be very hard and time consuming. We at PFP understand the needs of our clients and have helped them getting their glue pot back to a perfect condition. Whether it is just a glue roller that needs new coating, a complete glue pot assembly or even rebuilding the glue pot with new bearings, heaters, etc. We can get the job done!

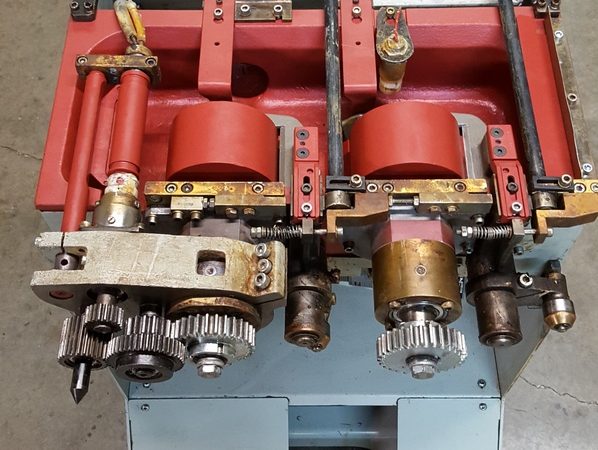

PUR coating

We completely strip the old parts by sandblasting them. In doing that, we clean and etch them to promote adhesion between the coating and the blasted part. After that they would go to the coating process where we apply 1 coat of primer, 2-4 coats of Ruby Red, and 4-6 coats of a clear topcoat. You will have multiple layers for wear resistance and nonstick. We ensure the whole part is completely coated 100%!

Benefits of investing in an additional PUR glue pot

When running PUR on a daily base even with a new coating the cleaning and preparing procedure of the PUR glue pot can be very time consuming. Having a 2nd glue pot and rotating them every day will save time. And once the time comes having to get a new coating, the second pot will make life easier as well.

Ask us about our current inventory for rebuild PUR glue pots!

Rebuilding EVA glue pots

EVA glue pots are probably the hardest working unit in a perfect binder while being the most neglected part as well. After years of production the condition of glue pots will get to a point where they create more issues and eat up time. Rebuilding a glue pot is very time consuming which is why PFP can offer complete rebuilds to get your glue pot back to its factory condition. We also offer rebuild EVA glue pots!